High Quality Tool Steel Die Steel

Basic Info

Model No.: 1.2714 1.2311 H11 H13

Product Description

Model NO.: 1.2714 1.2311 H11 H13

Steel Grade: Prime Steel

Technique: Forged

Surface Treatment: Bright Surface

Application: Die Steel Bar

Transport Package: Wooden Packing

Origin: Jiangsu China

Standard: AISI, ASTM, DIN, JIS, GB, BS

Composition: Alloy Steel

Shape: Bar

Special Use: High-strength Steel Plate, Free Cutting Steel, Mold Steel

Trademark: KAIXIN

Specification: 200-2000

HS Code: 7228400000

Product Description

High Quality Tool Steel Die Steel

Our products are mainly used in valve industries.We can provide many kinds of casting parts/stamping parts/Machining parts and forging parts.

1. Free forging, Die forging ,stamping, machining,heat treatment,ring rolling, drill hole.CNC machining.

2. Applied software for specification drawings: Auto CAD, Solidworks.

3. Precision machining: CNC, milling machine, drilling machine, numerical lathe, all types of lathe.

4. Surface finish process: polishing, sand blasting, heat treatment, painting, powder coating, anodizing, electroplating, mirror polishing.

5. Good quality and strict delivery time.

Products

Fob Price:Negotiable Trade Term:FOB SHANGHAI or CIF /CFR discharging port

Supply Ability: 2000MT/Month

Mini Quantity:1 piece

Port:Shanghai Port

Payment Terms:T/T, L/C, D/P

Size:Diameter≤Φ2000

Material:Alloy steel ,Carbon steel, Stainless Steel

Features:forged +machined /Ring rolls+ machined

Applications: Pressure container forgings transmission gears flanges

Clients: supplier /manufacturer /company /factory /distributor /agent /final user

Marketing Area: All over the world

| Grade | Standard | Round Bar Size:mm | Flat Bar Size:mm | Condition of Delivery | |

| Tool steel | 1.2083 / X42Cr13 | DIN Standard | Φ100~Φ1000 | 180×180~800×1500 | Hot Forged+Annealed+Machined |

| Annealed | |||||

| 1.2311 / 40CrMnMo7 | DIN Standard | Φ100~Φ1300 | 180×180~1000×2000 | Hot Forged+Annealed+Machined | |

| Normalizing + tempering, Or annealing | |||||

| 1.2343 / X38CrMoV5-1 | DIN Standard | Φ100~Φ1000 | 180×180~800×1500 | Hot Forged+Annealed+Machined | |

| Annealed | |||||

| 1.2344 / X40CrMoV5-1 | DIN Standard | Φ100~Φ1000 | 180×180~800×1500 | Hot Forged+Annealed+Machined ; | |

| Annealed | |||||

| 1.2365 / X32CrMoV3-3 | DIN Standard | Φ100~Φ1000 | 180×180~800×1500 | Hot Forged+Annealed+Machined ; | |

| Annealed | |||||

| 1.2367 / X38CrMoV5-3 | DIN Standard | Φ100~Φ1000 | 180×180~800×1500 | Hot Forged+Annealed+Machined ; | |

| Annealed | |||||

| 1.2550 / 60WCrV7 | DIN Standard | Φ100~Φ1000 | 180×180~800×1500 | Hot Forged+Annealed+Machined ; | |

| Annealed | |||||

| 1.2713 / 55NiCrMoV6 | DIN Standard | Φ100~Φ1300 | 180×180~1000×2000 | Hot Forged+Annealed+Machined ; | |

| Normalizing + tempering, Or annealing | |||||

| 1.2714 / 56NiCrMoV7 | DIN Standard | Φ100~Φ1300 | 180×180~1000×2000 | Hot Forged+Annealed+Machined ; | |

| Normalizing + tempering, Or annealing | |||||

| 1.2767 / X45NiCrMo4 | DIN Standard | Φ100~Φ1300 | 180×180~1000×2000 | Hot Forged+Annealed+Machined ; | |

| Normalizing + tempering, Or annealing | |||||

| H11 | ASTM A681 | Φ200~Φ1000 | 180×180~800×1500 | Hot Forged+Annealed+Machined ; | |

| Annealed | |||||

| H13 | ASTM A681 | Φ100~Φ1000 | 180×180~800×1500 | Hot Forged+Annealed+Machined ; | |

| Annealed | |||||

| D2 | ASTM A681 | Φ200~Φ700 | 180×180~500×1100 | Hot Forged+Annealed+Machined ; | |

| Annealed | |||||

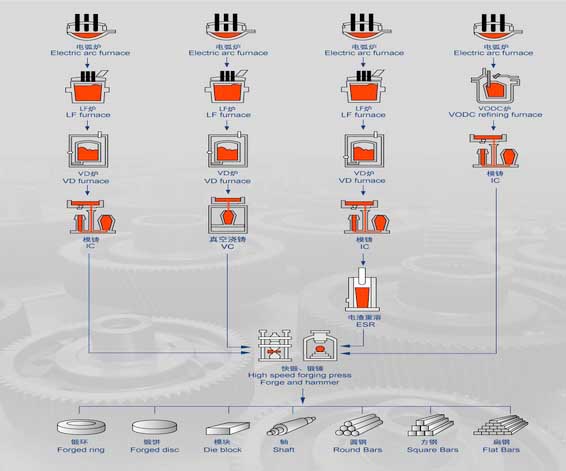

Forging Process

Equipments

8 SETS OF CNC MACHINES

1 large CNC gantry machining center

Other advanced professional equipments such as horizontal boring machine/miller/multi-function drilling and gace grinding machine.

58 sets of heat treatment equipments :normalizing, annealing, ion nitriding, carburizing, permeability of carbon and nitrogen, quenching and tempering, stainless steel solid-dissolve and aging, salt-bath quenching etc.

ALL KINDS OF TESTING MACHINES :CMM(three-coordinate measuring machine)HARDNESS,MECHANICAL TEST ,UT /MT TEST ,CHEMICAL COMPOSITION , INCLUSION RATINGS

Our Services

24 hours online service

Enquiry will be replied in 2 hours

One year warranty

1%-2%Spare Parts

CKD and SKD are available

Free parts for any breakdown with convincing eviden

Our Advantages

1. High quality and professional manufacturer

2. Advanced equipments for testing and manufacturing

3. Customized service according to your inquiry

4. Short lead time

5. Good after-sale service

Packing & shipment

1.Container Load: bubble bag, or plastic bag

2.Outer Packing: carton case or poly wooden case

3.small batch by courier , large batch by sea or air

4. Special requirement from customer is accepted.

FAQ

1 Are you a manufacturer, trading company or a third party?

We are a manufacturer, and we have started our factory & production since1988.

2 Where is your factory located?

Our factory is located in Jiangyin city, Jiangsu Province, China, near Shanghai city.

3 How can I go to your factory?

You can fly to Shanghai Pudong or Hongqiao International airport directly, and then take the bus to our factory. There are just 2 .5 hours from Shanghai. If you are in China ,you can fly or take the train to Wuxi city ,and take the bus to our factory.

You are sincerely welcome to visit our factory at any time!

Contact us if you need more details on Forged Parts. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Forged、Spare Parts. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Forged Parts

Premium Related Products

Other Products

Hot Products

Euro- Standard Custom Made Gear WheelCheap Machine Parts Shaft Step ShaftsGear for Reducer with High QualityNon-Standard Custom-Made Transmission Gear ShaftHigh Quanlity of Automotive Water Pump BearingAuto Parts Auto Bearing Made in China Ball-Ball SeriesBespoke Forged S355L Rolling RingProfession CNC Machined Roller Bearing ManufactureTransmission Parts Gear Box Parts GearFactory Price OEM Stainless Steel 304 316 Pipe FlangeSteel Forging Shaft with Stainless Steel Material FactoryTransmission Straight Teethed Bevel Helical Gear with KeywaySteel Hot Forging TubeSteel Forged Ring with MachiningDie Forging Steel Ring for Auto PartsDurable Stainless Steel Forged Rolling Ring