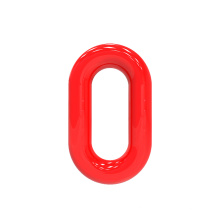

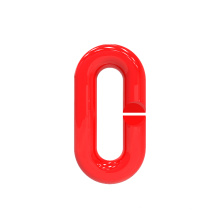

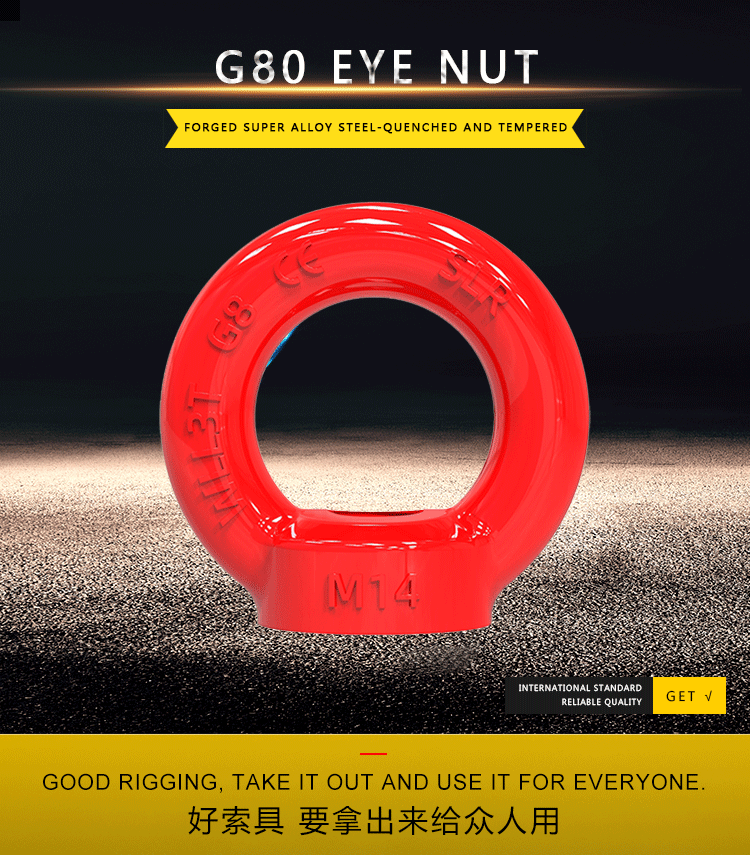

Rigging G80 alloy steel lifting point eye nut for lifting

Product Description

♦

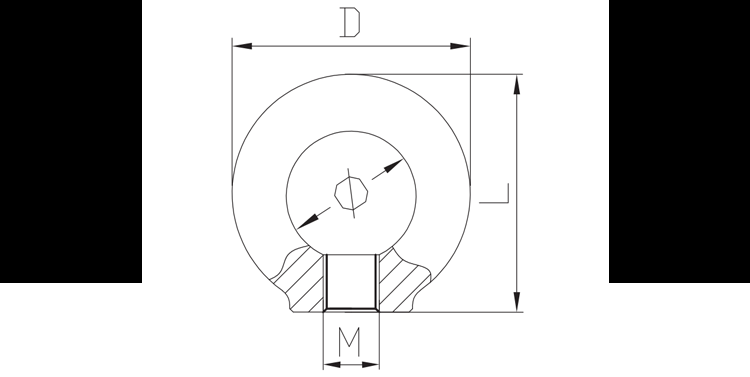

PRODUCT DESIGN RRAWING

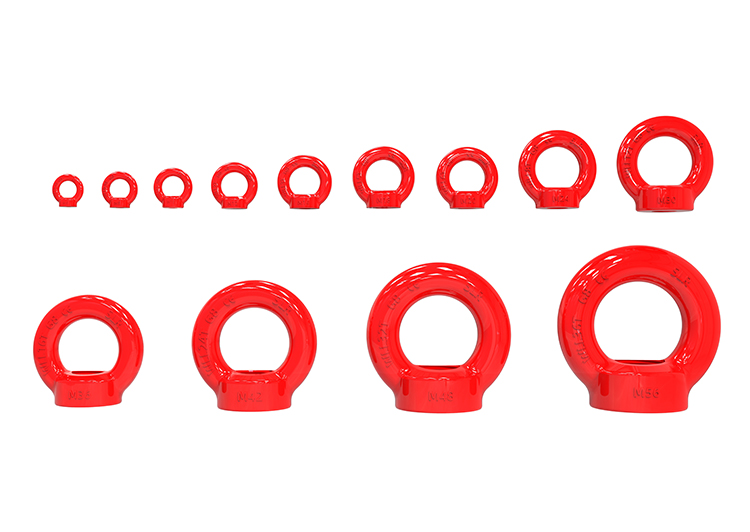

SLR-055 EYE NUT

♦

PARAMETERS

| ITEM NO. | WEIGHT/(Kg) | WLL/(T)(4:1) | Torque(N.M) | D | φ | L | |

| WLL 0° | WLL90° | ||||||

| 8-SLR055-M6 | 0.05 | 0.4 | 0.15 | 36 | 20 | 36 | |

| 8-SLR055-M8 | 0.05 | 0.8 | 0.4 | 10-15 | 36 | 20 | 36 |

| 8-SLR055-M10 | 0.09 | 1 | 0.4 | 10-15 | 45 | 25 | 45 |

| 8-SLR055-M12 | 0.16 | 2 | 0.75 | 10-15 | 54 | 30 | 53 |

| 8-SLR055-M14 | 0.24 | 3 | 1 | 20-30 | 63 | 35 | 62 |

| 8-SLR055-M16 | 0.24 | 4 | 1.5 | 20-30 | 63 | 35 | 62 |

| 8-SLR055-M18 | 0.34 | 5 | 2 | 72 | 40 | 71 | |

| 8-SLR055-M20 | 0.36 | 6 | 2.3 | 50-70 | 72 | 40 | 71 |

| 8-SLR055-M22 | 0.58 | 7 | 2.8 | 81 | 45 | 81 | |

| 8-SLR055-M24 | 0.72 | 8 | 3.2T | 130-160 | 90 | 50 | 90 |

| 8-SLR055-M27 | 0.72 | 10 | 4 | 180-220 | 90 | 50 | 90 |

| 8-SLR055-M30 | 1.32 | 12 | 4.5 | 200-250 | 108 | 60 | 109 |

| 8-SLR055-M33 | 1.29 | 14 | 5 | 250-270 | 108 | 60 | 109 |

| 8-SLR055-M36 | 2.10 | 16 | 7 | 280-400 | 126 | 70 | 128 |

| 8-SLR055-M39 | 2.09 | 20 | 8 | 280-400 | 126 | 70 | 128 |

| 8-SLR055-M42 | 3.11 | 24 | 9 | 500-600 | 144 | 80 | 147 |

| 8-SLR055-M45 | 3.05 | 28 | 10 | 500-600 | 144 | 80 | 147 |

| 8-SLR055-M48 | 5.02 | 32 | 12 | 500-650 | 166 | 90 | 168 |

| 8-SLR055-M52 | 4.94 | 36 | 13.5 | 166 | 90 | 168 | |

| 8-SLR055-M56 | 6.69 | 40 | 15 | 600-900 | 184 | 100 | 187 |

| 8-SLR055-M64 | 9.30 | 50 | 17 | 600-900 | 206 | 110 | 208 |

♦ Notes ♦

1) Before each use, the operator must perform a safety inspection on the sling and use it only after being qualified;

2) The sling must be inspected regularly by professionals (trained qualified personnel) every month;

3) If it is found that the dimensional wear of the sling is greater than 5% of the original size, it must be replaced in time;

4) If it is found that the amount of dimensional deformation exceeds 3% of the original size, it must be replaced in time to ensure safety.

♦

COMPANY PRODUCT DISPLAY AND PACKAGING

Forging or casting with high-quality raw materials

Strengthen source management and select high-quality materials.

Shandong Shenli Rigging is skilled at craftsman at heart.

Test piece by piece at 2.5 times working LOAD LIMIT

Every set of magical rigging must pass the standard test.

Thousands of roads, safety first, quality clearance is our first criterion.

Magnetic particle inspection for all products

Each set of magic rigging must be magnetic particle inspection.

Non-destructive testing Preventing trouble before it happens .

magnetic particle inspection makes you safe and secure.

♦

COMPANY LIVE

♦

WORKSHOP EQUIPMENT

♦

CERTIFICATIONS

···

Authoritative certification Trustworthy

♦

COMPANY HONOR

Selling is just the beginning ...

Genuine security

The products sold from this store are genuine products of Shandong Shenli Rigging Co., Ltd. Please rest assured.

Color difference description

The product pictures in the product details page are used for store decoration. Please refer to the actual product for color and texture.

Shipping methods

In order to meet the different needs of everyone, please contact customer service to negotiate the transportation method of the goods.

Delivery time

In view of the particularity of the rigging industry, the surface of the product and the typing of the product itself must be customized at any time according to customer requirements.Please contact customer service for delivery time.

Other considerations

Scrap standards:

1) crack;

2) The wear on the dangerous section is 10% of the original size;

3) The opening degree is increased by 15% than the original size;

4) The torsional deformation of the hook body exceeds 10%;

5) Dangerous section of hook or plastic deformation of hook neck;

6) The size of the hook after the handle is corroded is less than 90% of the original size;

7) When the bushing bushing wear reaches 50% of the original size, the bushing should be replaced;

8) When the abrasion of the hook mandrel reaches 5% of the original size, the mandrel should be replaced.

| CONTACT US |

Product Categories : Lifting Point&D Ring > Lifting Point&D Ring

Premium Related Products